Platinum Finishing Paint Booth Systems

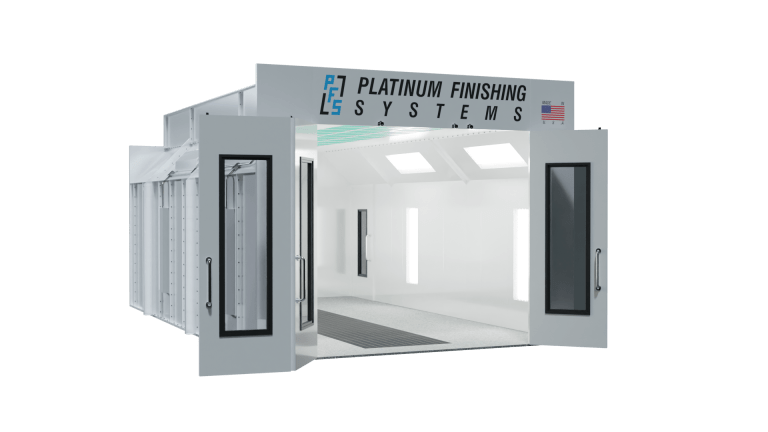

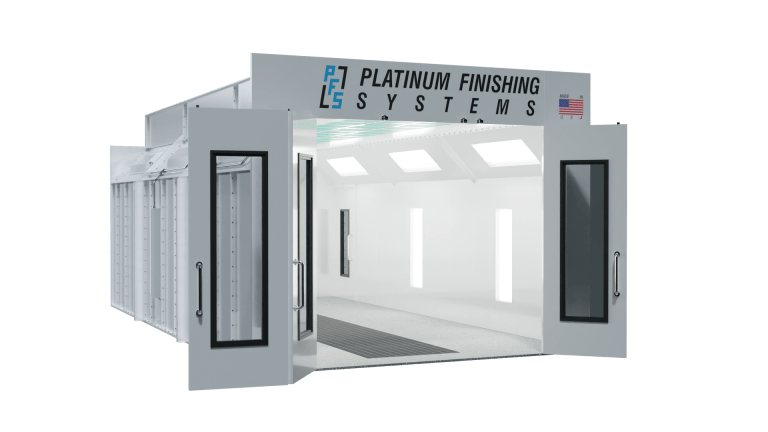

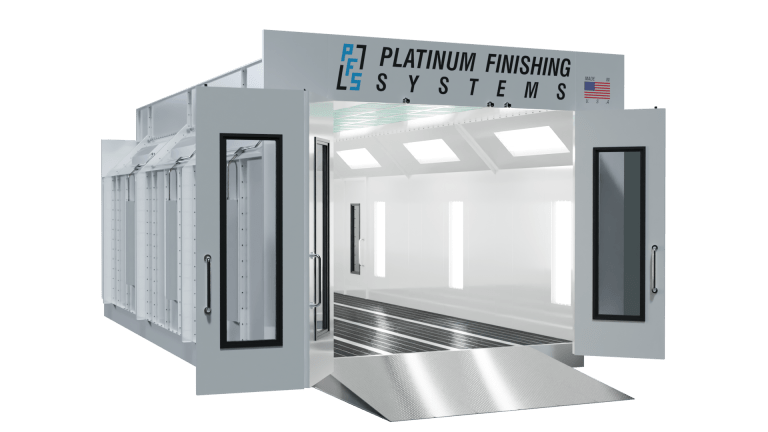

Platinum Finishing Paint Booth Systems Platinum Plus Full-Down Draft Paint Booth

Platinum Finishing Paint Booth Systems Platinum Plus Full-Down Draft Paint Booth

Couldn't load pickup availability

Share

Platinum Finishing Paint Booth Systems Platinum Plus Full-Down Draft Paint Booth

Description

How To Get A Quote:

Option 1:

“Contact Us to make sure you are getting the best unit possible. These machines are complex so let us help you get exactly what you need!

Option 2: (quickest response times)

Step 1. Add the item to your cart

Step 2. Checkout or Click on the Chat button box that is at the bottom right of your screen

Step 3. Please tell us any info you think we would need to know

Step 4. Relax, our team is processing your request and an expert will be in touch to get you exactly what you need!

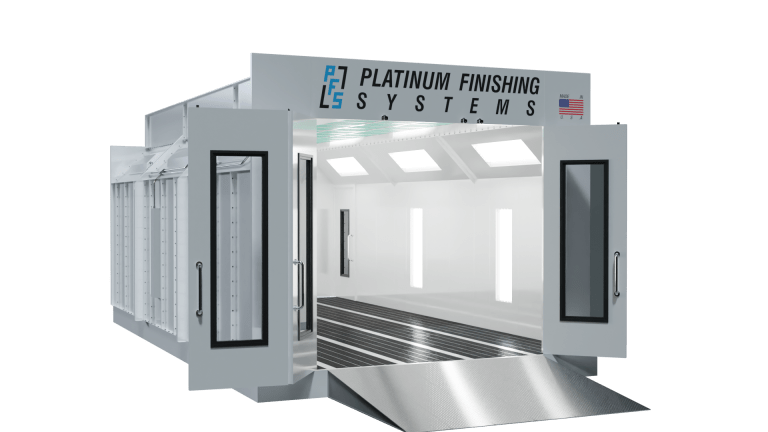

Downdraft booths are widely recognized as the most effective airflow style for superior overspray and contaminant control. In these booths, air is introduced through a full-length filtered ceiling. It then flows vertically over the product and is directed into a filtered exhaust pit located in the floor. You can also opt for a raised basement or concrete pit as needed.

Standard Full-Down Draft Paint Booth Package Included:

Booths are equipped with the following:

Our booths meet the rigorous safety standards outlined in NFPA-33, the highest-level safety code in the USA for the spray application of flammable or combustible materials.

These models have undergone thorough testing and hold certification as ETL-Certified Booths by Intertek/ETL (Edison Testing Labs). They are also recognized by OSHA (Occupational Safety & Health Administration) as NRTLs (Nationally Recognized Testing Laboratories). This certification is often required by local authorities to ensure safe operation and regulatory compliance.

Rest assured, ETL certification is included with your purchase!

ETL Certification included with your purchase

- Assembly instructions.

- UL approved components.

- Air Flow Type: Air enters the booth from the full filtered intake ceiling on the paint booth is exhausted straight down though the filtered floor.

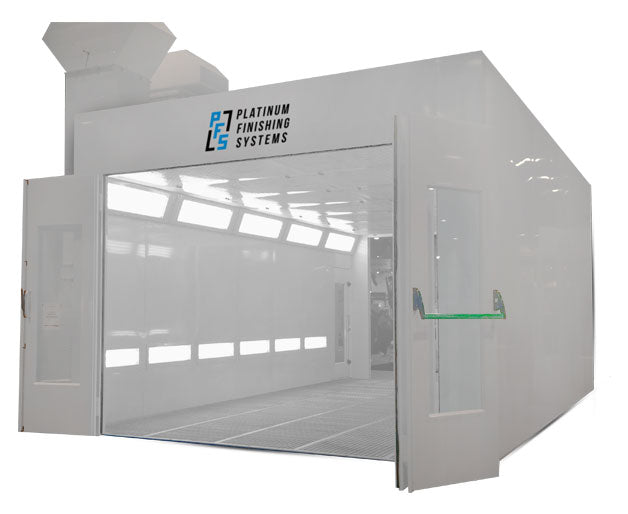

- Construction: 18 Gauge Galvanized Steel pre punched holes for nut and bolt assembly.

- Filters: Fiber Glass exhaust rolls and Blanket Type filters.

- Lighting: LED Lighting or T8 Lighting four tube 4’ Light fixtures ETL listed.

- Doors: Double Wall doors (filtered or with observation Windows) & (1) Personnel Door.

- Fans: Tube Axial Fans with non-sparking blades motor sizes vary with booth size.

- Optional: Powder coating, raised basement, LED lighting, height extensions.

- Optional :Heater 1.0MBTU burner with spray, bake and cool downs,

Why Choose PFS Full-Down Draft Booths?

The Platinum Plus Full-Down Draft booths are renowned for their exceptional airflow management, ensuring efficient overspray and contaminant control. In this configuration, air is introduced through a fully filtered ceiling that travels vertically across the product before being directed into a filtered exhaust pit located in the floor. Additionally, you have the option to incorporate a raised basement or concrete pit as required.

PFS designs and manufactures all paint booth models in-house, ensuring efficiency and compliance with industry standards. Whether you’re using solvent-based, waterborne, or a combination of coatings, PFS offers comprehensive solutions. We can create a custom booth tailored to your specific needs and requirements, all while exceeding NFPA, OSHA, and ETL requirements.

- ETL listed manufacturer

- Best pricing in the industry

- Lowest lead times in the industry

- Fully customizable paint booths

- Certified in all US states

- Exceed all local and national codes

- Modular paint booths can be expanded

- National service and installation

Design and Construction

At PFS, all our paint booths are crafted from durable 18GA galvanized steel and precision-machined using CNC equipment. This ensures a perfect fit and finish, accompanied by straightforward assembly instructions. Our booths feature a hassle-free assembly process with nut, bolt, and self-tapper components for easy installation.

Moreover, our paint booths undergo a powder coating process, making them resistant to corrosion and UV damage. This not only enhances durability but also results in a brilliant white finish, improving visibility both inside and outside the booth.

Quality Products

All our spray booths are proudly crafted in-house at our Santa Rosa, CA facility. We oversee every step of the manufacturing process, guaranteeing the industry’s finest spray booth quality at competitive prices. Each element of your booth is meticulously designed and tailored to precise specifications.

What’s more, we hold ETL listings and approvals across all jurisdictions, streamlining the approval process and ensuring a faster return on investment (ROI).

Air Filtration

PFS employs a cutting-edge “high-velocity” exhaust system, which is enhanced by fiberglass exhaust filters to create a pristine, dust-free environment. Every booth we ship comes equipped with standard 20×20 heavy-duty fiberglass exhaust filters and tacky intake filters.

Fans and Motors

Our belt-driven tube axial fans feature a streamlined belt tunnel that draws in outside air to ventilate the drive compartment efficiently. The steel housing undergoes an iron phosphate process for rust protection and is finished with a durable acrylic epoxy paint. The factory-installed cast-iron sheave is directly assembled on the fan shaft. When you order the complete fan with drive package, motors and belts are packed separately.

Rest assured, these fan and motor packages are engineered for exceptional longevity, surpassing any other combination in the market.

Parts and Accessories

PFS paint booths are shipped complete with all essential components, including nuts, bolts, gaskets, caulking, tempered glass for light covers, detailed instruction manuals, assembly drawings, wiring diagrams, parts manuals, and a comprehensive parts list that outlines every included item.

Optional Items

- Tri-fold Doors

- Upgraded LED lighting

- Double Wall insulated panels

- Viewing windows

- Filtration systems

- Cooling systems (on applicable models)

- Heating systems (on applicable models)

- Humidity Controls (on applicable models)

- Motor upgrades

- Roof height extensions

- Powder coating

How To Get An Options Quote:

Option 1:

“Contact Us to make sure you are getting the best upgrades & options possible. These containers are complex so let us help you get exactly what you need!

Option 2: (quickest response times)

Step 1. Add the item to your cart

Step 2. Click on the Chat button box that is in the bottom right of your screen

Step 3. Please tell us which Upgraded options you are looking for and any info you thinks relevant

Step 4. Relax, our team is processing your request and an expert will be in touch to get you exactly what you need!

Made in the USA

At PFS, we take pride in our in-house manufacturing of paint booths and enclosures, ensuring top-notch quality and competitive pricing. We are committed to ongoing innovation and design enhancements to meet local and national codes and requirements. Contact us today to discuss a custom solution for your next project!